Cheese, like many of our favourite foods, is susceptible to spoilage by micro-organisms present in and on the raw materials required for their production. For those making cheese, inadequate hygiene at the point of milking, soil, and poor quality silage provide an easy entry point for micro-organisms into the milk, including Clostridium tyrobutyricum.

This gram-positive bacteria is particularly infamous for causing late blowing defects in cured, hard and semi-hard cheeses, dramatically reducing quality, rendering it entirely unmarketable. Cheese makers have been trusting Bioseutica’s® LYSOLAC® for over 30 years to naturally prevent late blowing, protecting their cheese and its commercial value.

Late blowing defects are associated mostly with the mild temperatures and high humidity of spring and autumn, but they can occur throughout the year. Late blowing is primarily caused by the spores of Clostridium Tyrobutyricum, notorious for their resistance not only to pasteurisation but also more modern approaches including bactofugation and microfiltration. While pasteurisation is able to effectively eliminate the vegetative, rapidly growing form of C. Tyrobutyricum, spores continue unharmed through the cheese making process, poised to begin growing during ripening when conditions are more favourable.

Once these spores germinate into vegetative cells, a process that only takes in the order of hours, they begin to convert lactate into butyric acid, acetic acid, hydrogen, and carbon dioxide. The acids give rise to unpleasant taste and smells, whereas the production of gases increases the pressure inside the maturing cheese, forming fissures, splits, and cracks that swell the cheese. In severe cases, this can cause the cheese to explode late in ripening, hence the name! A solution to late blowing without affecting the taste and organoleptic properties of cheese does exist, however, and that is Bioseutica®’s LYSOLAC®.

LYSOLAC® Mode of Action

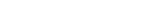

LYSOLAC® Inhibits growth of Clostridium tyrobutyricum

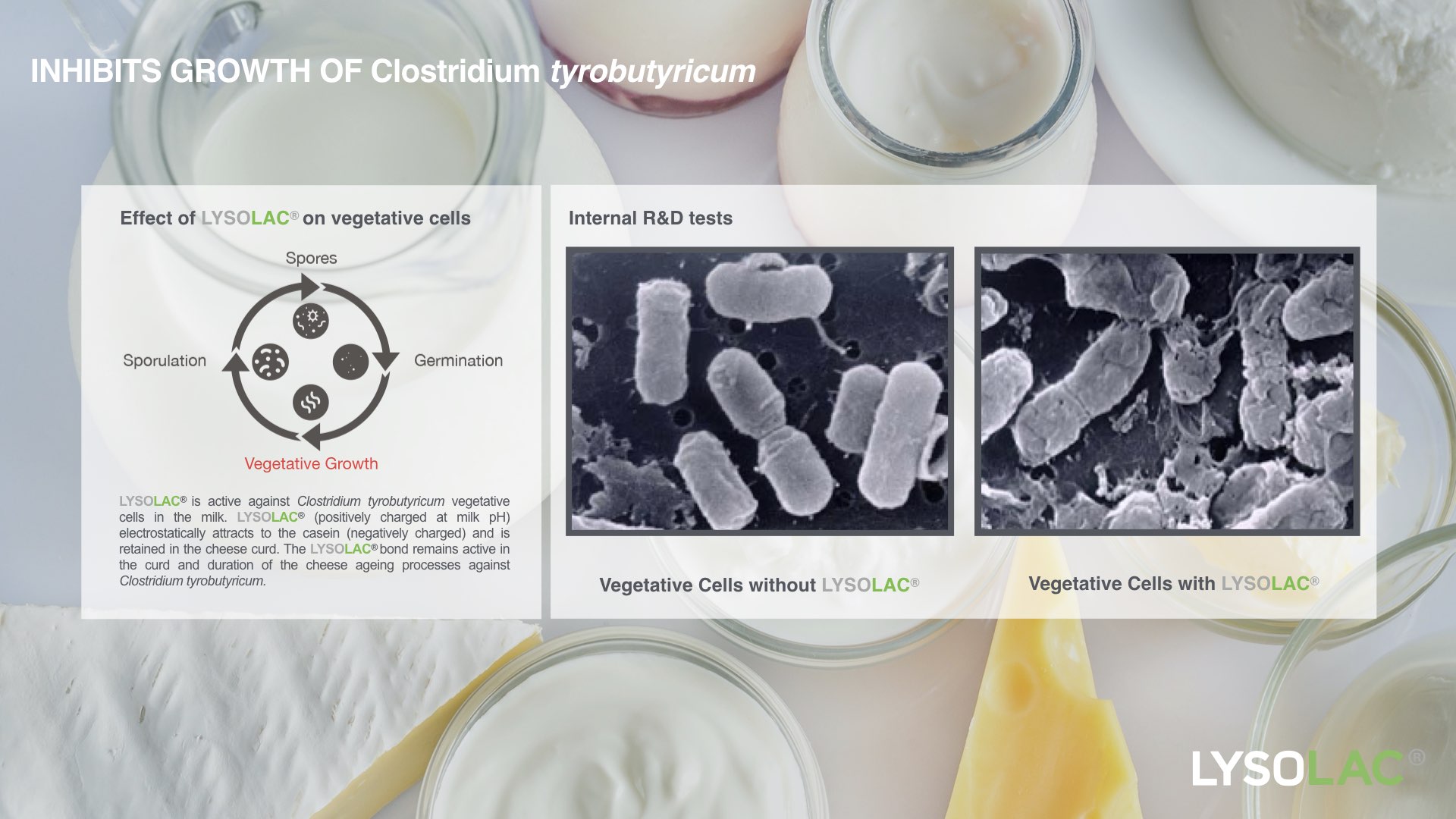

Interaction between LYSOLAC® added and the casein in the milk

LYSOLAC® successful track record of over 30 years

LYSOLAC® is composed of Lysozyme, a powerful natural anti-microbial enzyme that effectively inactivates gram-positive bacteria by rupturing their protective peptidoglycan outer cell wall. LYSOLAC® is easy to use for cheese makers; when added to the milk it protects the cheese throughout processing, and into the ripening stage. Being cationic, that is positively charged, LYSOLAC® is specifically attracted to negatively charged milk casein, binding to it, allowing LYSOLAC® to remain active in the curd, and beyond into ripening. This remarkable property means that Clostridium tyrobutyricum spores that do become vegetative during cheese ripening are rapidly destroyed, entirely preventing late blowing defects. This property allows LYSOLAC® to increase the shelf life of cheeses including Grano Padano DOP, Edam, Gouda, Manchego, Cheddar, and Emmentaler among others. Indeed, 99% of Italian Grano Padano DOP makes effective use of Lysozyme, with 85% of French hard cheese producers doing the same. These cheese makers recognise the tangible benefit of Lysozyme, with LYSOLAC® costing a mere €0.04 per kilo of the finished cheese.

Consumer cheese and dairy preference varies quite significantly across regions. In the EMEA, consumers are increasingly seeking products that contribute positively to their gut, health, and wellness; products made with natural ingredients, from local dairy sources, with animal welfare in mind. As a natural additive, LYSOLAC® is USDA approved for use in organic cheeses, and classified as a food by JECFA, making it the perfect protection for your cheese. For the APAC region, consumer preference and growth centres on cheeses to be eaten on the go. These processed cheeses also benefit from LYSOLAC®, particularly in increasing its shelf-life whilst maintaining texture, and flavour. LYSOLAC® is easy to use, effective, and economical, providing cheese makers with protection for their precious cheese.

Advantages

- Prevents late blowing in cheese

- Prevents cracks/slits in cheese

- Prevents holes formation in cheese

- Avoids unpleasant taste & aromas in cheese

- Prevents off-flavor in cheese

- Reduces gas production in cheese making

- Allows Superior cheese production

- Enhances cheese safety

Regulatory Status

USA: In 2007 Alcohol & Tobacco Tax and Trade Bureau (TTB), US Department of Treasury added lysozyme to the list of enzymatic activity materials authorised for use in wine production (27 CFR 24.246). In 2008, TTB concluded that lysozyme is also appropriate for use in the production of beers up to 500 milligrams per litre. EU: COMMISSION REGULATION (EU) No 1129/2011 of 11 November 2011

- G.R.A.S. status granted by the USA F.D.A. in March, 1998

- Approved in Canada in 2000 under Food and Drugs Act (1122)

- Approved in Europe as food additive in ripended cheese and products

- Registered in EU as approved food ingredient: E1105*

- FSSC 22000 certification ( Food Safety Systems Certification)