LYSOLAC®: trusted to protect the cheese for 30 years naturally

Cheese is susceptible to spoilage by micro-organisms, which can cause defects that dramatically reduce quality, imparting harmful odors and taste defects. LYSOLAC® has been trusted by cheesemakers for over 30 years to naturally protect the quality of cheese, maintaining its flavor and texture while increasing shelf-life.

LYSOLAC® is safe, easy to use, and cost-effective. This protective enzyme, found in mothers’ milk, tears, and hens’ eggs, powerfully disrupts the membrane of gram-positive bacteria, killing them.

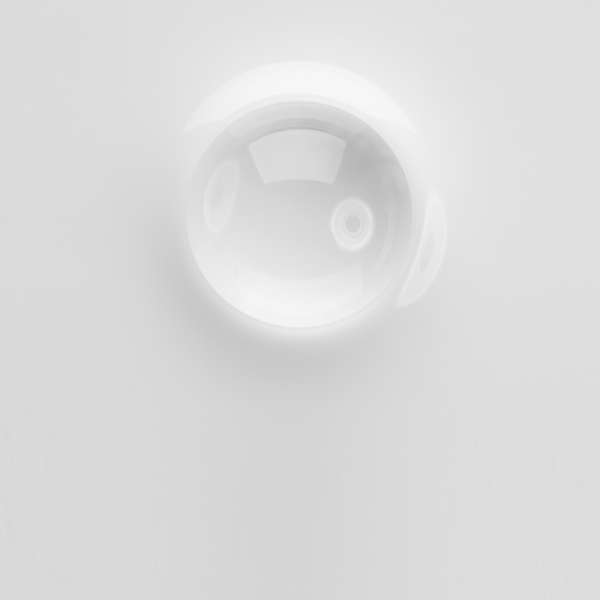

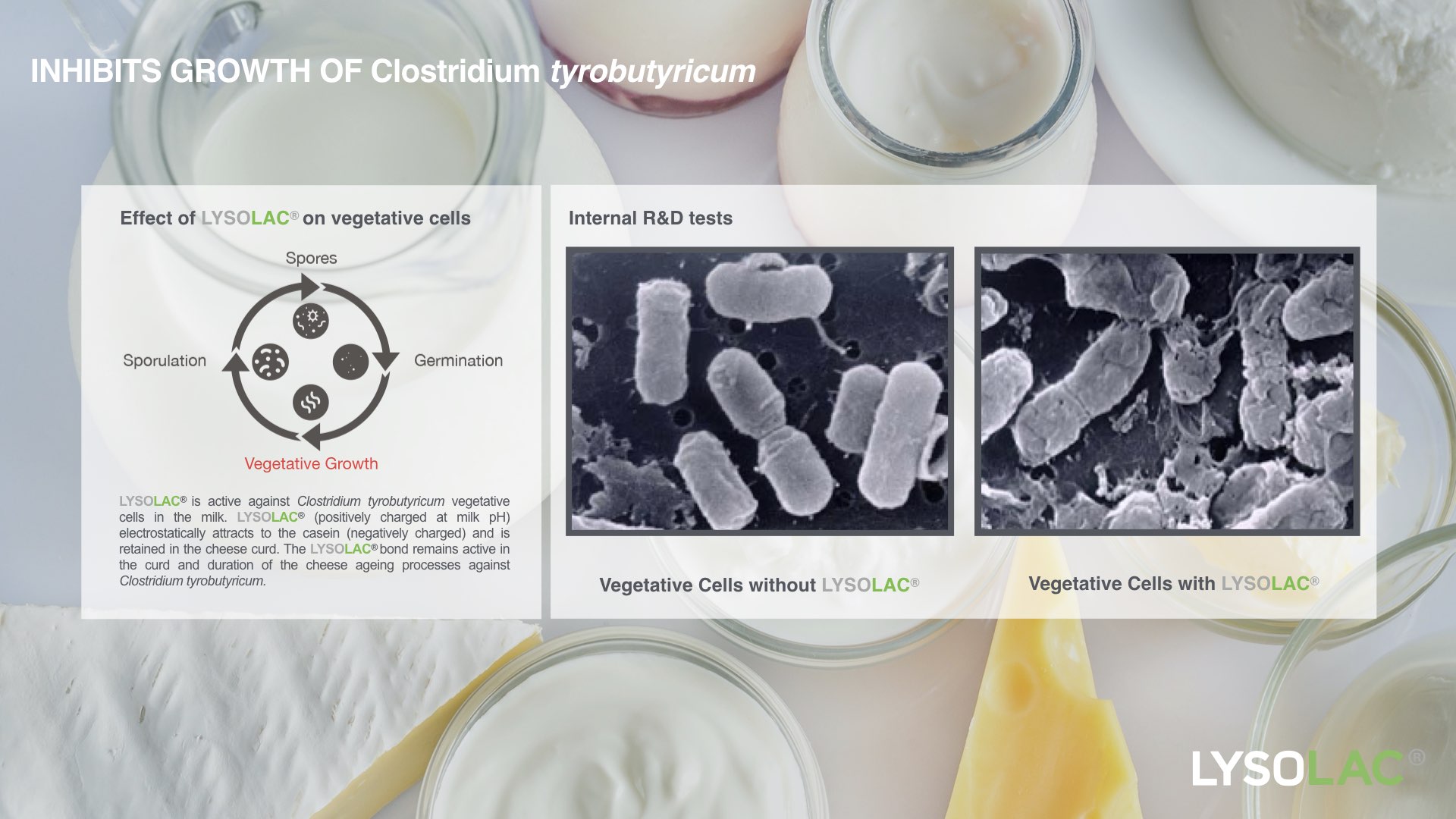

When added directly to the milk, LYSOLAC® protects the cheese throughout the process. Its positive charge binds it to the negatively charged casein in milk, keeping LYSOLAC® active in the curd and beyond into the ripening stages. This is critical for preventing late-blowing, cracking, and splitting defects caused by Clostridium tyrobutyricum spores. These spores are notoriously resistant to pasteurization, bactofugation, and microfiltration approaches. They endure these unharmed, poised to grow weeks later during ripening when favorable conditions are favorable. Cheese protected with LYSOLAC® rapidly destroys Clostridium tyrobutyricum spores that begin to develop during ripening, entirely preventing late-blowing spoilage of cheese.

LYSOLAC® Inhibits growth of Clostridium tyrobutyricum

Interaction between LYSOLAC® added and the casein in the milk

LYSOLAC® successful track record of over 30 years

LYSOLAC® is invaluable insurance for cheesemakers, costing only 0.04€ per kilo of the finished cheese. 500g of LYSOLAC® is enough to treat 16.5 Kilolitres of milk, providing cheesemakers with real tangible value. Available in either granulated or liquid forms, LYSOLAC® is stable for up to 3 years when kept dry at ambient temperatures.

Protect your precious cheese naturally with LYSOLAC®:

Advantages:

- Cost-effective insurance against late-blowing defects

- Easy to implement, requiring no specialist equipment

- Preserves starter cultures

- Does not alter the final cheese product's flavor, texture, or aroma.

Use Cases:

- Improvement of yield in cheese production

- Prevention of late-blowing, cracking, and slit formation

- Enhancement of cheese safety and consistency of quality

Formulation:

LYSOLAC® is available in various quantities as a granular or pre-mixed solution. 50 g is enough to treat 4000 lbs of milk (450 gallons or 1700 liters). Use the calculator to the right or download a dosage chart. LYSOLAC® Granular is available online in 50 g and 100 g re-sealable pouches and 500 g screw-top canisters. LYSOLAC® is available in special orders containers of 10 kg, 20 kg, and up; it has a shelf life of 2 years when kept free from sunlight and heat. LYSOLAC® can also be ordered as a solution in containers of 20 Ld on up to 1000 L, with a shelf life of 9 months when kept free from humidity and heat. LYSOLAC® is stable and safe: Granular remains stable when maintained free from moisture at ambient temperature (15-25°C) with a shelf life of 3 years: premixed solution remains stable with a shelf life of 1 year.

Dosage:

25-35 mg of LYSOLAC® per liter of milk is sufficient to avoid late-blowing. 500g of LYSOLAC® can treat 16.500 liters of milk (88.000 lbs).

Regulatory:

- JECFA classification as food

- GRAS certified in 1998: US FDA

- Approved in Canada in 2000: Food and Drugs Act (1122)

- EU registered food ingredient: E1105, 1129/2011

- FSSC 22000 Food Safety Systems Certification

- Available certified Halal and Kosher upon request

Regulations may vary by country. Always check the local legislation regarding the usage and claims of this product.

References:

- Khorshidian N., Khanniri E., Koushki M.R., Sohrabvandi S., Yousefi M. An Overview of Antimicrobial Activity of Lysozyme and Its Functionality in Cheese | Publisher Site