LYSOVIN is used as a preventative and cure in the winemaking industry, protecting wine from spoilage caused by contamination of lactic acid bacteria. Winemakers have trusted a flexible, natural additive, LYSOVIN, for over ten years to enhance and protect their wine's quality and consistency while reducing their dependence on sulfites.

Lactic acid bacteria (LAB) can grow at any stage of the winemaking process, even remaining dormant until conditions are suitable, spoiling wine post-bottling. Finding their way into the must on the grapes, LAB growth flourishes in the case of damaged fruit due to mechanical harvesting by birds or through dehydration during heatwaves. Poor equipment sanitation can also provide a route for unwanted LAB species, including Lactobacillus spp., Pediococcus spp., Oenococcus oeni, Pediococcus damnosus, Pediococcus parvulus, and Leuconostoc mesenteroides among others.

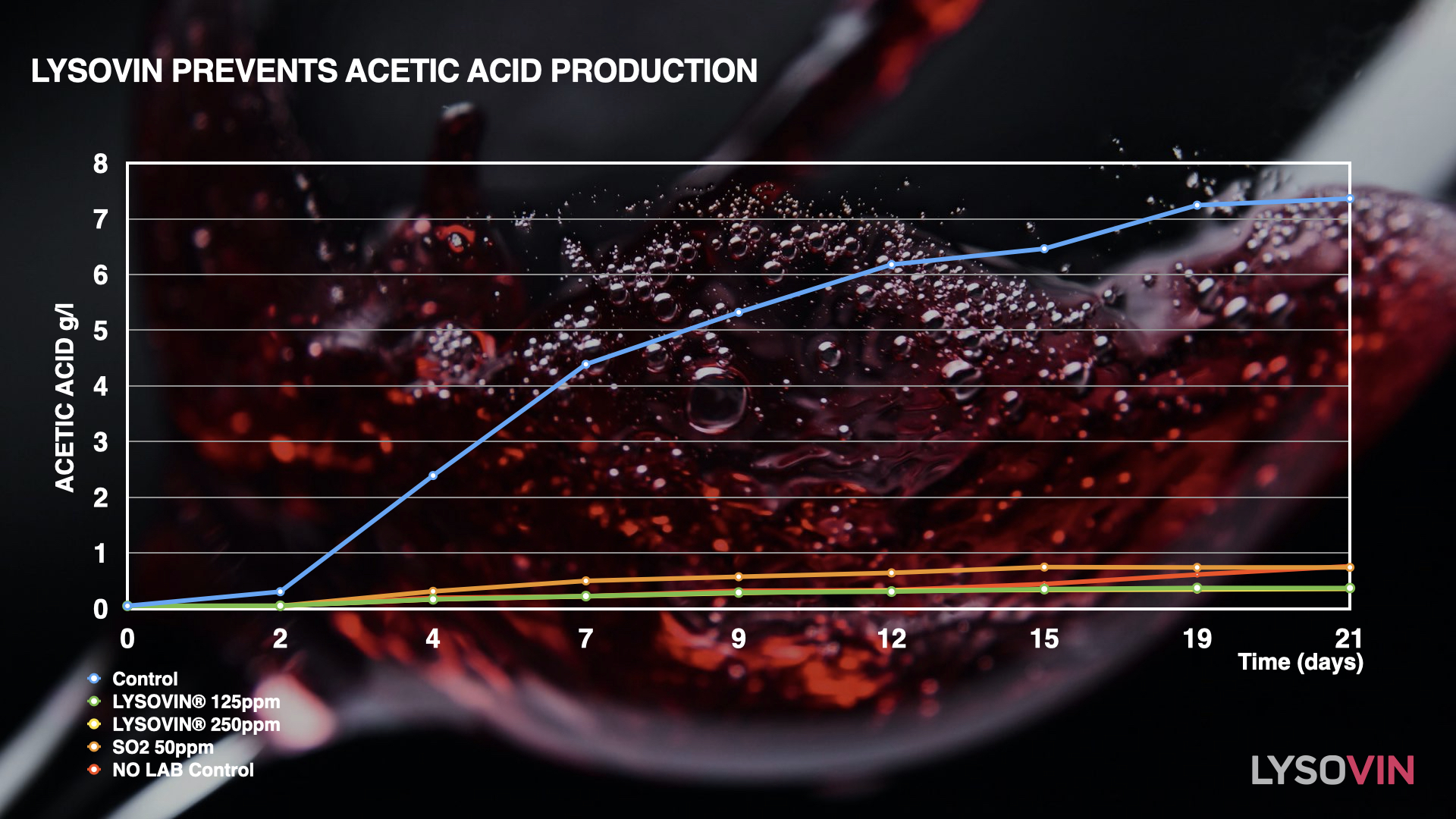

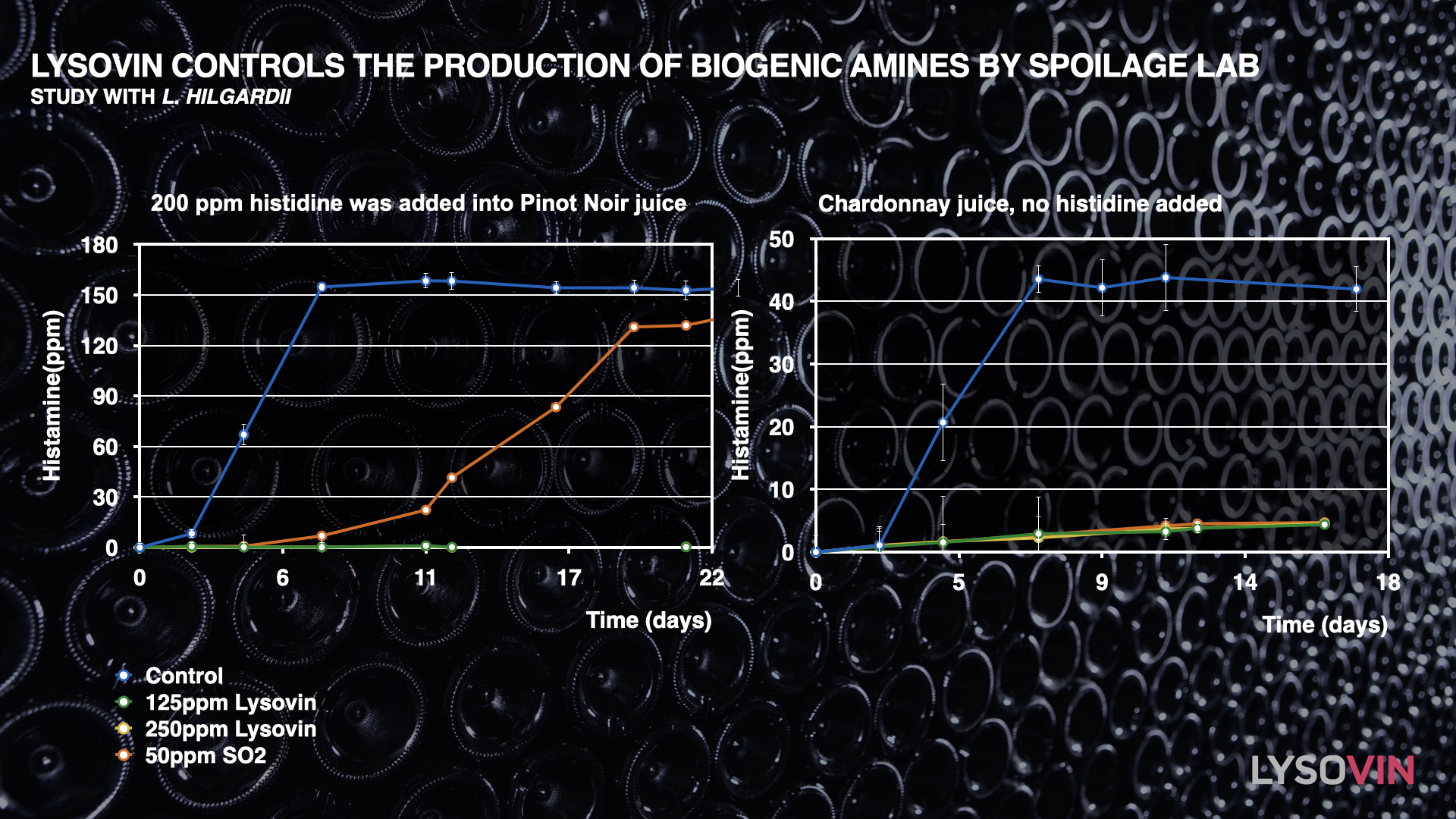

The negative impact of LAB contamination in the winemaking process is multi-faceted. Not only do LABs compete with the yeast for berry sugar, reducing alcoholic fermentation, but they also produce unwanted volatile acids and biogenic amines, including histamine, cadaverine, and putrescine. These negatively impact the organoleptic qualities of wine, dramatically affecting the aroma, acidity, and taste.

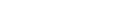

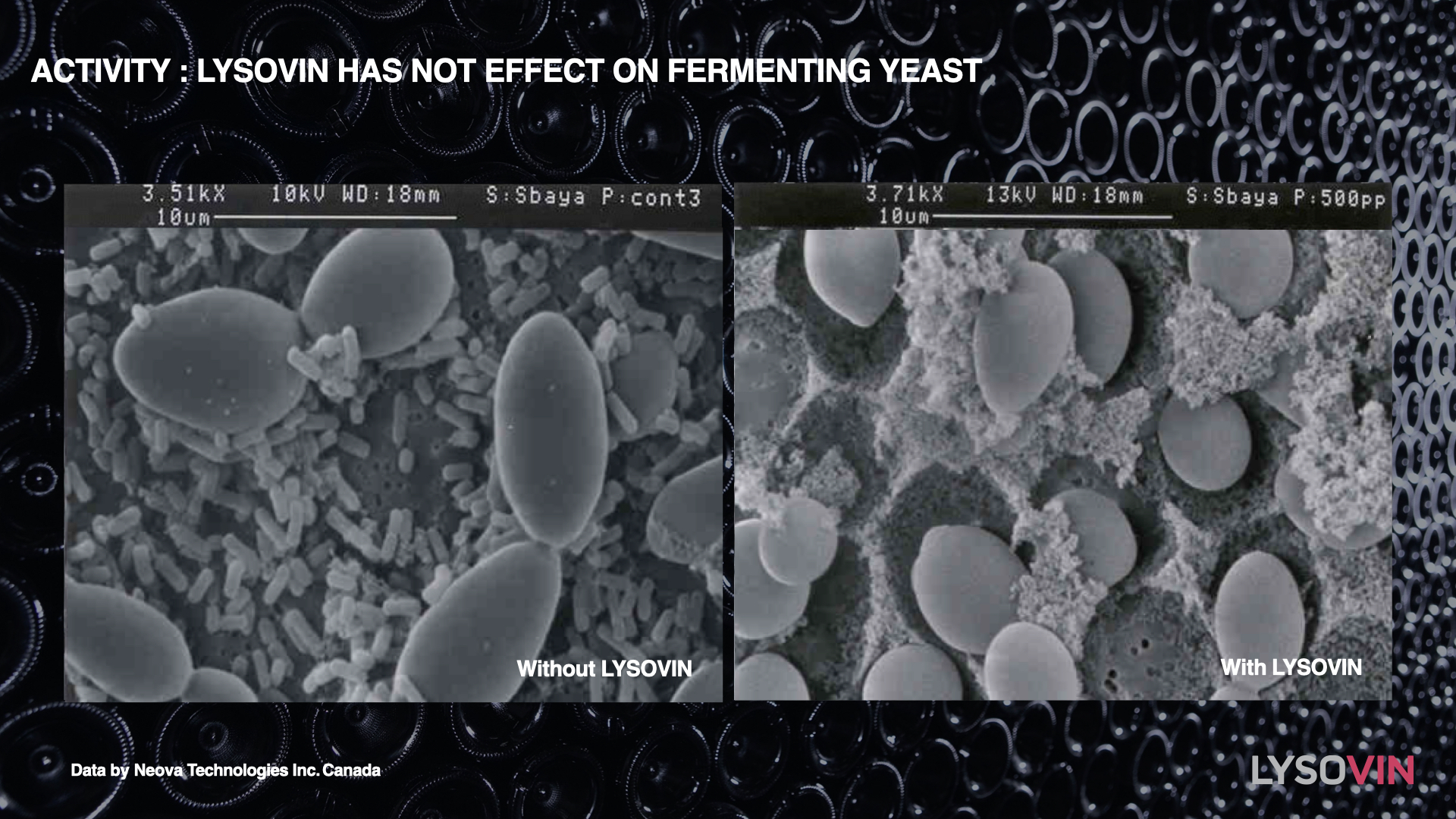

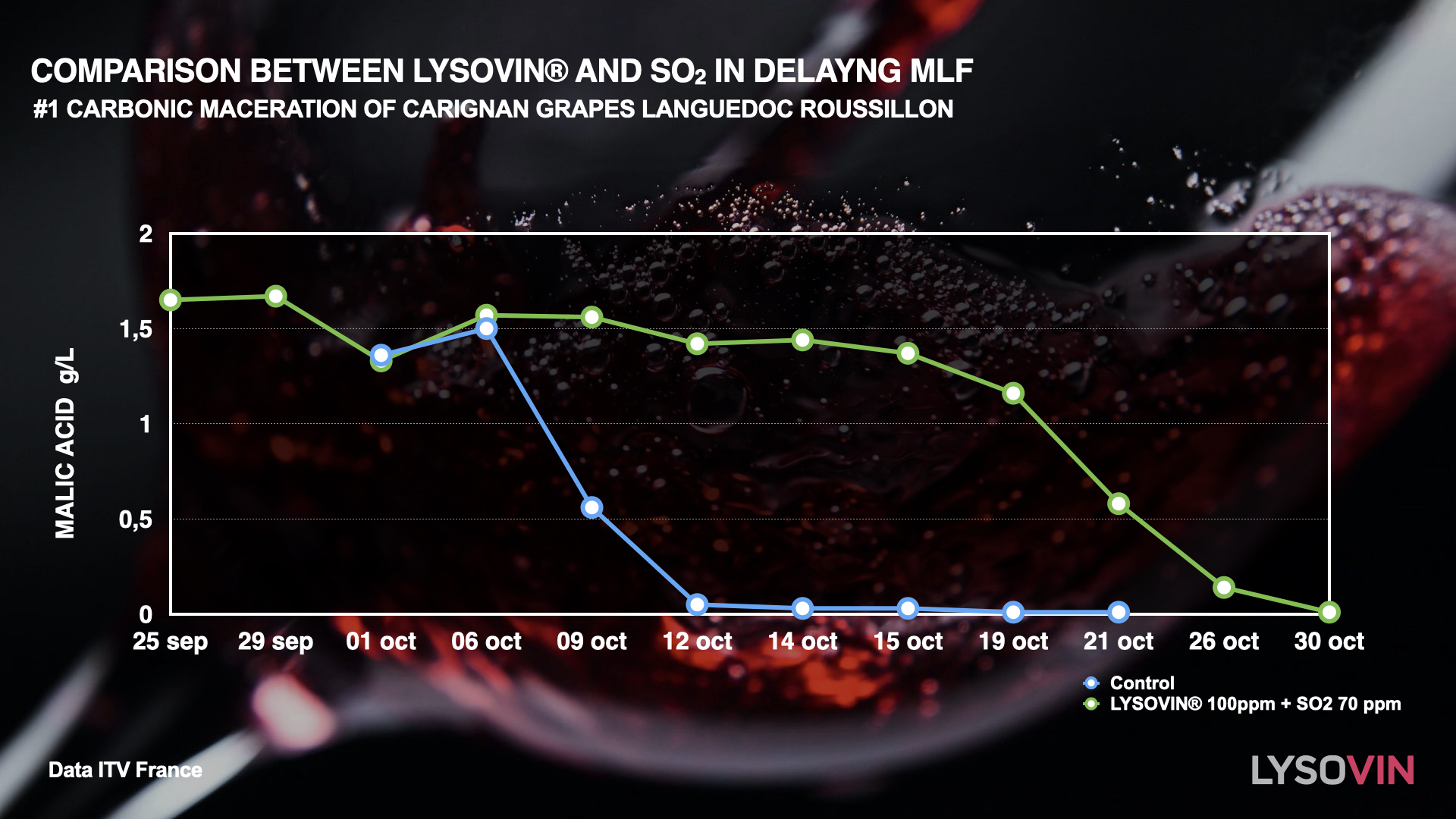

LYSOVIN prevents faults during winemaking, including acidification, geranium character, mousiness, and overproduction of diacetyl. When added directly to the must before settling, LYSOVIN stabilizes the wine, maintaining low levels of biogenic amines while protecting and leaving the yeast unaffected. Bioseutica’s LYSOVIN can also be used to control the onset of malolactic fermentation (MLF or malo), reducing the production of biogenic amines. The microbiological stability of wine can also be maintained by delaying the growth of strains of Oenococcus oeni once MLF is completed. Adding LYSOVIN also stabilizes the wine during aging, even in high-acidity wines where the efficacy of SO2 decreases dramatically.

LYSOVIN in wine

LYSOVIN is our patented solution to preventing bacterial contamination while reducing sulfite use in winemaking. Following tests by Italian and French authorities, LYSOVIN has been approved for winemaking since 1995. Bioseutica has also obtained permission from the TTB (Alcohol and Tobacco Tax and Trade Bureau) for LYSOVIN’s use in winemaking in the USA.

LYSOVIN is the trusted natural way to improve wine's stability, texture, aroma, and shelf-life.

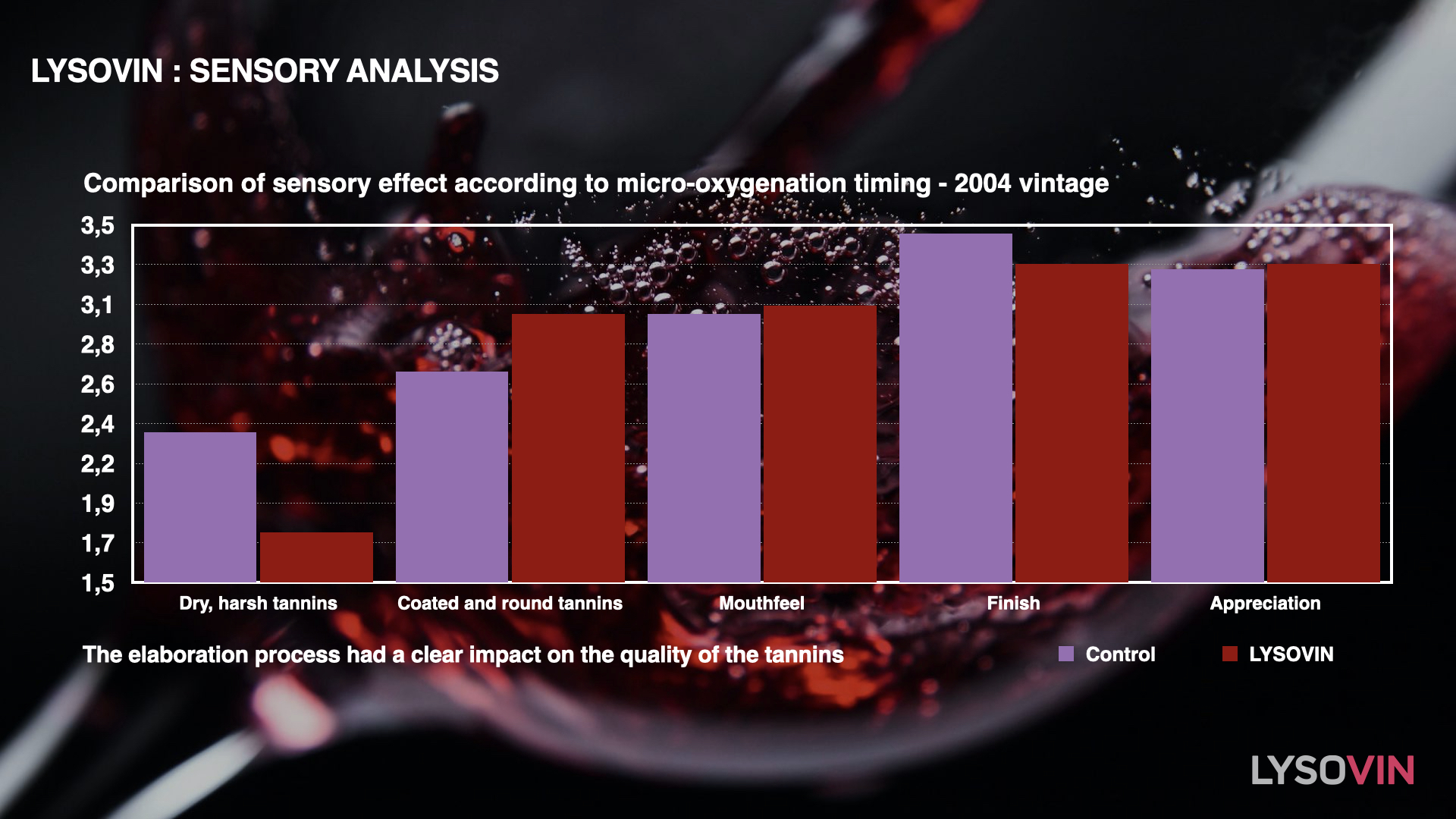

LYSOVIN Sensory Advantages

Advantages

- Preserves the wine yeast

- Protects the wine from spoilage

- Stabilizes the wine and prevents bottle fermentation during aging

- Allows reduction or delay to S02 use (Sulfur dioxide, sulfites)

- Stops growth of lactic acid bacteria (LAB) in must and juice

- Prevents the growth of Brettanomyces strains in wine, even in the absence of S02

Sensory Advantages

- Controls the production of compounds causing organoleptic defects

- Controls diacetyl levels in wine

- Reduces production of acetic acid and biogenic amines (Histamines)

- Stops mousiness, acrolein/bitterness, geranium character, mannitol

- Aids polyphenols development by delaying S02 addition

- Improves the stability, texture, aroma, and shelf life of wine

- Preserves the color intensity of the wine

Use Cases

- Optimization of MLF to desirable levels

- Preventing, Delaying, Modulating, and Stopping MLF

- Microbiological stabilization post-MLF

- Inhibiting MLF when blending partial or complete MLF wines

- Winemaking of different types of wine by precisely managing MLF

- White winemaking with aging on the lees without MLF

- White winemaking without MLF with a delay of S02 stabilization to avoid reductive aromas

- Sparkling winemaking without MLF

- Red winemaking without MLF

- Improving MOX Mycrooxygenation applications by delaying MLF

- Reducing or eliminating sulfites in wine

- Producing low/no-alcohol (LNA) wines and wine waters

Regulatory Status

- Certified Kosher

- Accepted by JEFCA-Joint FAO/WHO Expert Committee on Food Additives

Selling Unit:

Kilograms(kg)

References

- K.Liburdi, I.Benucci, and M.Esti; Lysozyme in Wine: An Overview of Current and Future Applications | Publisher Site

- Sonni, F.; Cejudo Bastante M.J., S.; Chinnici, F.; Natalia N.; Riponi C.; Replacement of sulfur dioxide by lysozyme and oenological tannins during fermentation: influence on volatile composition of white wines | Publisher Site

- V. Gerbaux, A. Villa, C. Monamy, A. Bertrand Am J Enol Vitic. January 1997 48: 49-54; Use of Lysozyme to Inhibit Malolactic Fermentation and to Stabilize Wine After Malolactic Fermentation | Publisher Site

- O. Ciosi, C. Gerland, A. Villa, O. Kostic Wine & Viticulture Journal Issue 2, 2008; Application of lysozyme in Australian Winemaking | Publisher Site

- Kai Chen, Shun-yu Han, Bo Zhang, Min Li & Wen-jun Sheng; Development of a lysozyme-combined antibacterial system to reduce sulfur dioxide and to stabilize Italian Riesling ice wine during aging process | Publisher Site

- Lopez Isabel, Pilar Santamaria, Carmen Tenorio, Patrocinio Garijo, Ana Rosa Gutierrez, Rosa Lopez; Evaluation of lysozyme to control vinification process and histamine production in Rioja wines | Publisher Site