Inspired by their first patient's death from limited Penicillin, Florey, Chain, and Heatley urgently increased production, turning to the US in 1941 amid UK constraints.

A nation’s entire supply of Penicillin

The death of their first trial patient through the insufficient supply of Penicillin drove Florey, Chain, and their research assistant Heatley forward with inspired momentum. Increasing production was an absolute necessity. Initial attempts in the UK fell short due to the destruction of pharmaceutical factories or prior commitments to manufacturing other drugs required for the war effort. The trio turned to the US in July 1941.

Connections made through the Rockefeller Foundation helped rally pharmaceutical companies, including Pfizer and Eli Lilly, to begin work on developing mass production methods for Penicillin. A promise of 1 kg of the wonder drug was made to Florey for sharing their methods, which at that point were painstakingly slow. The mold was grown using rudimentary equipment - bedpans and open-top tins, but with the newfound pharmaceutical expertise, the first breakthroughs came quickly. Deep-tank fermentation allowed the mold to be grown submerged with constant aeration and stirring, unlocking massively scaled-up production.

Mouldy Mary’s Cantaloupe

The search was then on for a more productive strain of mold, and the answer came from a rotting cantaloupe found in a fruit market 160 miles south of Chicago. ‘Mouldy Mary,’ as Mary Hunt had fondly come to be known, had found a mold producing six times more Penicillin than the original strain. Indeed, the mold on this chanced-upon rotting cantaloupe remains the ancestor to the strains of Penicillium used today.

The next breakthrough was again one of chance. After Heatley had run out of glucose, a key component of the growth media used in the Oxford labs, a colleague suggested substituting corn-steep liquor, an abundant corn industry by-product in the mid-West. This amino-acid, vitamin and mineral-rich waste product proved an exceptional nutrient source for the mold, massively improving Penicillin yields.

Penicillin arrives in Europe

Three years after Florey, Howard, and Chain’s landing in the US, production of Penicillin had gone from a 1% to an 80-90% yielding process. The newly developed deep-tank fermentation methods enabled the production of 21 billion doses in 1943 to balloon to 6.8 trillion in 1945. Single doses, initially costing $20, 250 times the cost of their weight in gold, came to cost only $0.06 by the war's end. The allies could now produce enough for their military campaigns, an effort estimated to have saved 300,000 soldiers’ lives in World War II. It was in this focus on the military campaigns that Florey’s promised kilo of Penicillin was forever forgotten.

The 1943 landing of the British Eight Army on Sicily saw the arrival of Penicillin in Italy for the first time. As the allies pushed northwards, they spread the word of Penicillin, though the supply remained limited. Its production outside of Italy, available only through imported aid via the United Nations Relief and Rehabilitation Administration (UNRRA), made fertile ground for the flourishing black market. Those with the right connections and enough money now had access to the drug.

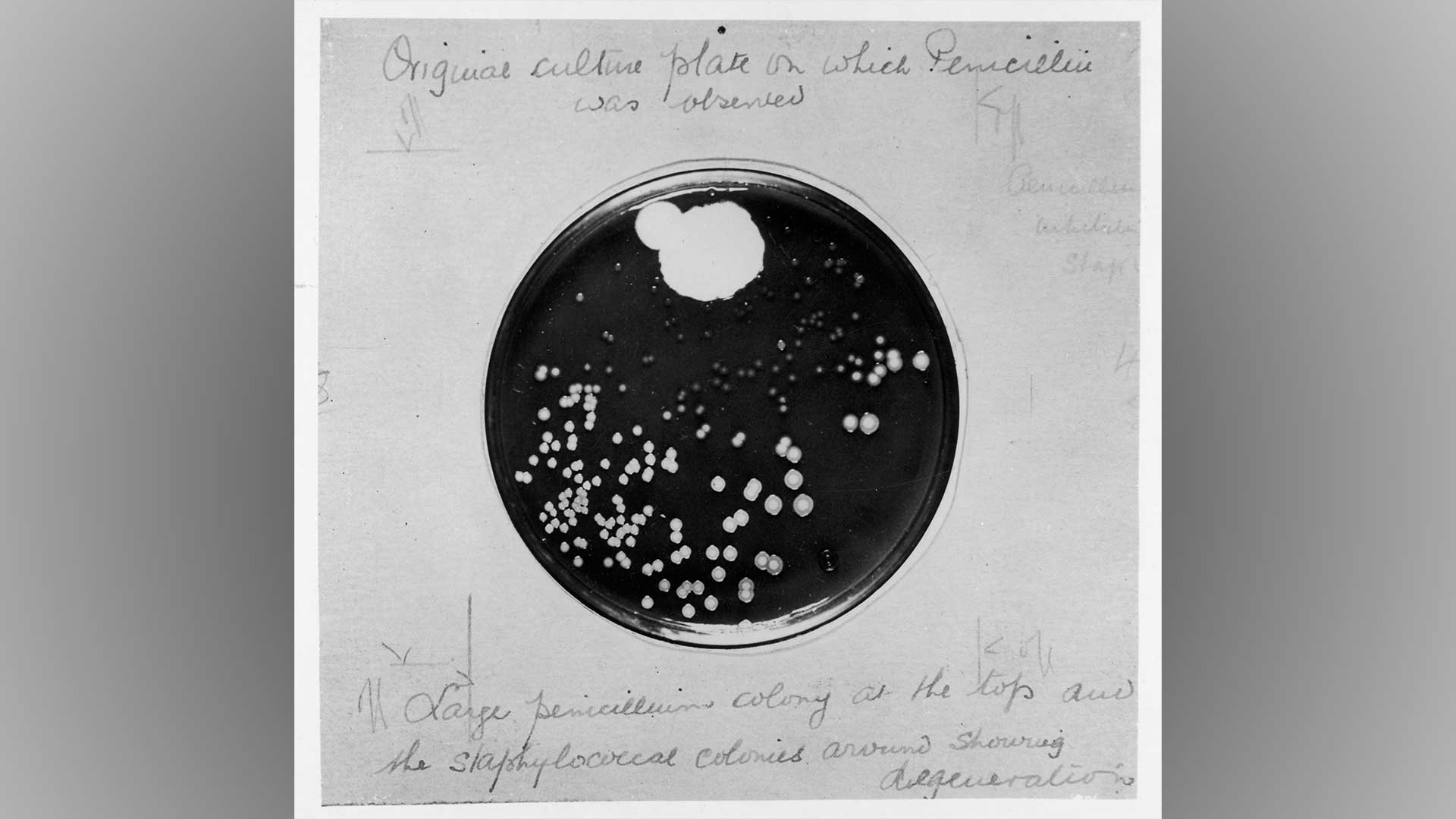

Photograph of the original culture plate in which Penicillin was first observed. ‘A large Penicillium mould colony at the top and the staphylococcal colonies around showing degeneration’

Penicillin comes to Italy. Local children hitch a ride on a Sherman tank of 3rd County of London Yeomanry (Sharpshooters) in Belpasso near Catania, Sicily, August 1943. (Source Wiki: Public Domain)

The root of today’s Penicillin moulds, a Canaloupe found rotting in a market

ENDIMEA (Ente Nazionale Distribuzione Medicinali agli Alleati) was established in 1944 to tackle this problem. This defined the requirement of provincial health offices to independently report regional demand to the General Directorate of Public Health (DGSP), who instructed ENDIMEA’s distribution of the then French and British-made Penicillin. Now the wonder drug was available to all for free by prescription, and the black market was stifled by the high margins offered to pharmacists. Careful tracking of on-ice shipments from warehouse to pharmacy further secured access to the antibiotic for all. Despite this, the continued reliance on imported Penicillin was clearly untenable. It is here that SPA’s story begins in 1947.

100 years of Lysozyme

2022 marks 100 years since news of Lysozyme’s discovery reached the Royal Society. Let us take you on the journey of this 100-year story: